In this article, we’ll be discussing a Shock Absorber by Ohlins Racing AB, US publication 20210140504. The publication date is May 13th, 2021 and the filing date is July 12th, 2019. This patent has not been granted yet.

Brief Summary (tl;dr)

Ohlins have created a new shock that they claim will be easier to service and will be much better at preventing dirt and dust from entering the shock itself. In short, there is an outer seal assembly and an inner seal assembly. There is then a locking ring to keep the outer seal assembly in place, which includes another seal (wiper). The outer seal includes a seal-oil-seal system, where there are two seals that sandwich an oil bath. The oil bath prevents shit from getting into your shock and also seals micro-scratches as the piston cycles. The locking ring threads onto the outside of the outer seal assembly to keep the two seals and oil in place. The inner seal is just a normal seal to prevent oil from escaping when the locking ring is removed. Replacing the outer seals and the oil bath only requires the removal of the locking ring, so you don’t have to get inside the shock to do a service to the seals.

Background

Ohlins has been a big-dog in the auto racing and moto world for a long time, bagging 300+ championships across all disciplines. A handful of years ago, Ohlins decided to jump into the mountain bike game, and eventually started bagging World Cup downhill wins and World Champs downhill gold medals with Loic Bruni. They’re no strangers to speed and, in my opinion, are a Top-3 suspension manufacturer in the world.

From my own personal experience, my wife had a Specialized Stumpjumper with an STX shock. Prior to the STX, it had a normal Rockshox, which felt fine, nothing wrong with it, but god damn did that STX make an incredible improvement. I tell you what, if Ohlins wasn’t so expensive, I’d have these on every one of my bikes. It felt that good.

As far as shocks go, a typical rear shock will employ what Ohlins calls an air-to-gas sealing system, where there’s a single rubber seal between the atmosphere and the air-side of the shock. This seal is designed to prevent air leakage and helps prevents shit from getting into the shock. Ohlins makes a good point, stating an issue with this design is the fact that even the smallest piece of dirt or scratch on the seal can result in air leakage very quickly, which has definitely happened to me. The flip side of this design is that it’s simple and easy to work on. An air-side service for a Super Deluxe costs me about $30 in parts and about 20 minutes of my time, so no big deal. So, why redesign what already works?

Intro

Ohlins have developed a new rear shocks system for a bike that utilizes what they’re calling an ‘air-to-liquid-to-gas’ sealing system – yes, they’ve added liquid to the sealing system. In short, they’re effectively using three sealing components (two assemblies) between the atmosphere and the air-side of the shock. One of the assemblies contains a seal-oil-seal system, meaning there’s an oil bath between the two seals. The other assembly is a single seal that prevents oil from releasing out of the shock when servicing the outer seals.

Additionally, Ohlins is claiming servicing will be rare and easy to do. The shock includes a ‘locking ring’ which holds the seal-oil-seal assembly in place on the outboard side of the housing. All you’ll have to do is unthread this locking ring and the seals and oil are right there to service. Most importantly, you’ll never have to actually get inside the shock to change these parts, as they’re separated from the inside of the shock with another seal, so you’ll be able to do some very simple and easy services when the time comes. FIG. 5a and b show the system in motion.

Intended Novelty

The intended novelty with this one appears to be the use of the air-to-liquid-to-gas system to seal a shock. In particular, it’s the liquid part that’s new. There are other subtleties that may relate to smaller legal novelties, but what we care about is the liquid portion of the sealing system. Since this isn’t granted, the language could change, but it’ll be close to this.

Why

Ohlins has three reasons for this new design – they want a smaller shock that has improved dust and dirt resistance and (most important to me) is easily serviceable.

However, a problem with shock absorbers comprising pneumatic springs is to make them small, resistant to dust and dirt, and easily serviceable.

The easily serviceable part is interesting to me. Do they mean it’s easily serviceable for them? Or for us? Will this shock actually be cheaper to service by a professional, since it’s easier to service?

In the end, Ohlins say:

[This shock] enables a number of advantages, for example the air-to-liquid-to-gas system of the outer seal creates a sealing which maintains very good sealing properties over a long time, thus increasing drastically the service intervals... [and this shock] provides excellent access to the outer sealing such that when replacement is required, this can be done without having to disassemble the entire shock absorber.

What

First, FIGs. 2 – 4 show a few views of the outside of this new shock. It looks like they’ll use a single rebound and two compression dials; I could have that backward. I’m pretty sure there are two compression dials, they don’t state multiple compression paths, but the images look like two dials.

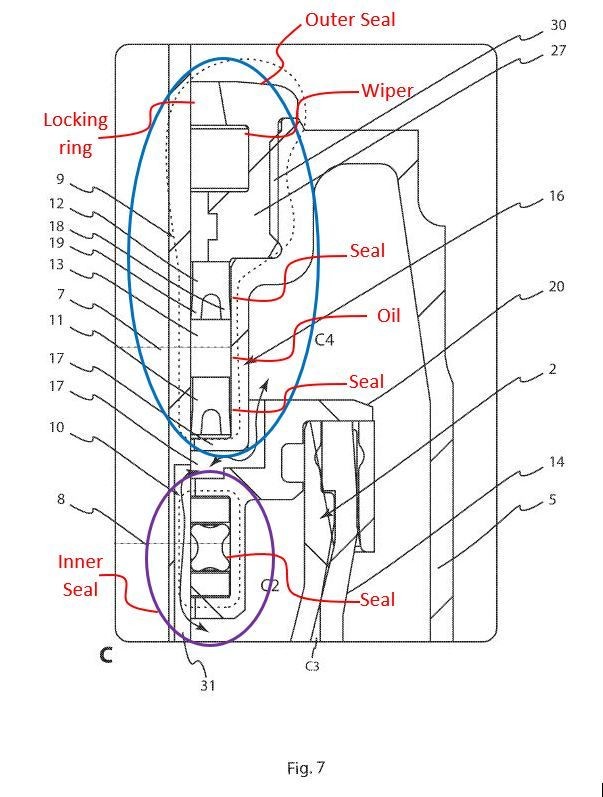

There are basically two distinct sealing assemblies in this design. The first is the outer seal assembly 9 (FIG. 7 blue oval) and the other is the inner seal assembly 10 (FIG. 7 purple oval). The outer seal assembly contains the two seals that sandwich the oil. The seals appear to be normal-ass seals, but it’s the oil that is interesting.

The outer sealing unit 9 includes an inner sealing member 11 and an outer sealing member 12 together defining a liquid space between the piston rod 4 and the housing 5, said liquid space 13 comprising a sealing liquid, such as damper oil.

The liquid part is very important, as Ohlins states:

Traditional air-to-gas sealing, common in air spring shock absorbers, are sensitive to dirt and... will cause quick loss of pressure in the gas spring. [This shock] minimizes this since there [are] two sealing members with a liquid filled space arranged therebetween, [therefore, this provides] two separate sealing members [and] also provides a liquid which can fill minor scratches in the surfaces of the piston rod and the sealing members, thereby minimizing pressure losses.

The inner seal is located in such a way that when you’re servicing the outer seals, damping fluid doesn’t pour out of the shock. If that seal wasn’t there, damping fluid would be everywhere and defeat the purpose of the locking ring.

As far as serviceability goes, Ohlins states that the locking ring 27, noted below in FIG. 6, can be removed without any special tools or processes. They state it will be threaded for easy removal to access the outer seal assembly, which again includes two seals and the oil bath. So, this means the outer seal assembly can be replaced without ever having to actually get into the shock itself. Additionally, the locking ring includes a ‘wiper’ 29 to keep even more shit from getting into your shock, though it doesn’t look like your typical wiper. Dope.

At service, the locking ring 27 is removed from the housing 5 where after the inner 11 and outer 12 sealing members are moved out of the housing 5 for inspection and optional replacement.

As far as dirt resistance goes, Ohlins states the use of the unique locking ring + wiper provides good dirt resistance capabilities.

The locking ring 27 not only locks the inner 12 and outer 12 sealing members but also protects the outer sealing unit 9 from dust and dirt by closely fitting with the piston rod 4 such that dust and dirt cannot pass between the piston rod 4 and the locking ring 27.

As far as the ‘smaller shock’ claim goes, Ohlins don’t really say shit about that. Maybe this is smaller than normal, because they don’t explain that claim.

And yes, this has an expanding bladder for that extra supple ride. Again, reference FIGs. 5a and b toward the top.

Conclusion

I see a lot of patent documents that have a very low chance of ever seeing the light of day. Most of them are complete garbage. Typically, you can tell whether an idea has legs based on the quality and completeness of the figures and explanation of a patent document. It means someone spent time and money on the idea and document. I’ll go out on a limb and say this one has a very good chance of being released to the public.

I’ll be the first to admit I am no suspension expert. I can do most air can services and fork air/damper services, but that’s about it. That being said, it appears as though Ohlins have figured out a genuine wholesale redesign of the typical shock that would benefit me greatly. The simple fact that major seals can be serviced without having to take the shock apart is wild.

But, I’ll say it, this appears to be much more complicated than any normal shock. Look at all these seals... an expanding bladder, four fluid chambers. I really like the idea, and I really like that they’ve come up with a very creative solution to a problem but damn, that’s a lot going on. It might be easy for a simple service, but what about a full service? Anyway, cool idea, Ohlins. - @wheel_based

View replies to: Ohlins New Easy-to-Service Mountain Bike Shock?

Comments